Navigating Food Safety Compliance: What F&B Managers

Food & Beverages

Power Every Process With Complete Operational Clarity

From ingredient traceability to safety audits, POSITIIVPLUS gives you one platform to control quality, ensure compliance, and optimize your entire food supply chain — all in real time.

The SaaS Edge

Centralized Quality

Control

Monitor every stage of production and supply chain in one secure platform to maintain food safety and regulatory compliance without juggling disconnected tools.

Real-Time Issue

Resolution

Get instant alerts and live dashboards to detect and respond quickly to quality deviations, supplier risks, or compliance gaps.

Transparent

Traceability & Reporting

Build trust with customers and regulators by tracking ingredient origins, production processes, and sustainability metrics — with automated reporting you can rely on.

What’s Possible

How POSITIIVPLUS Revolutionizes

Food & Beverage Operations

End-to-End Traceability

Managing raw materials, supplier certifications, and production lines across multiple locations can be complex. POSITIIVPLUS centralizes all this data, enabling you to trace ingredients from source to finished product. This visibility helps you quickly isolate quality issues, manage recalls, and maintain consumer trust.

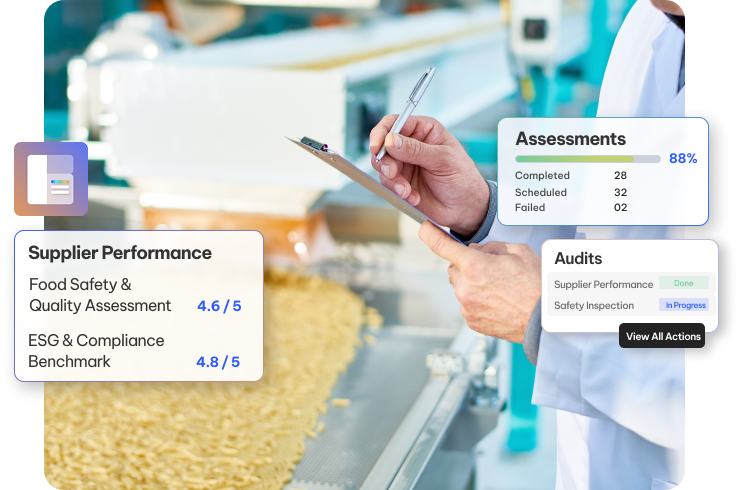

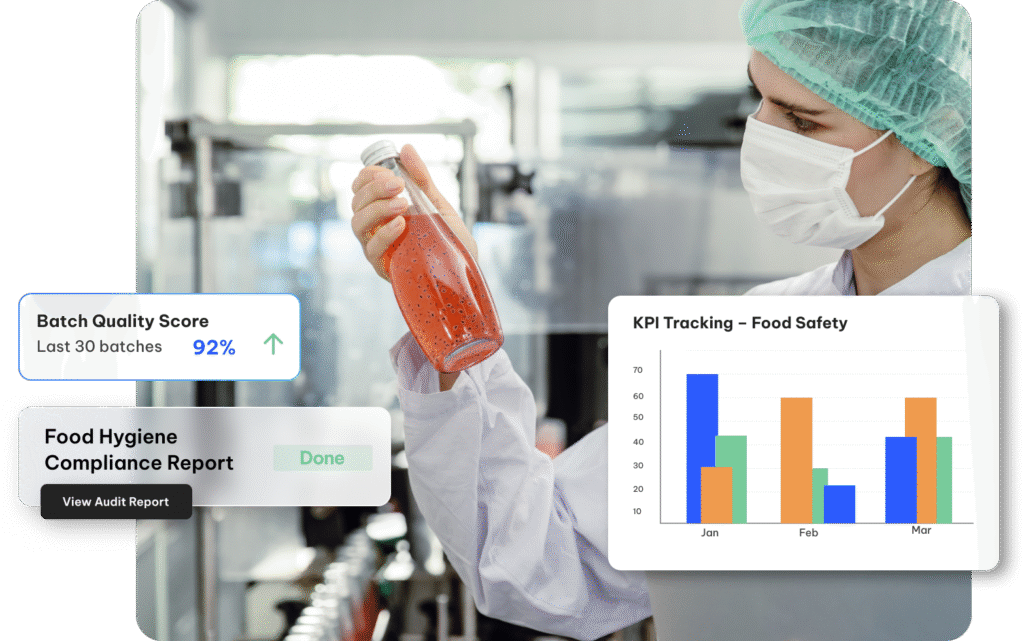

Consistent Quality, Every Batch

Stay ahead of quality control, compliance, and safety requirements. POSITIIVPLUS is your digital hub for assessments, audits, and corrective action assignments — whether for ingredient inspections, supplier performance, or hygiene checks. All updates are stored securely in our Data Manager, so your teams always have the information they need to keep production running smoothly.

Prevent losses from quality issues with structured

assessments, targeted actions,

and regular audits.

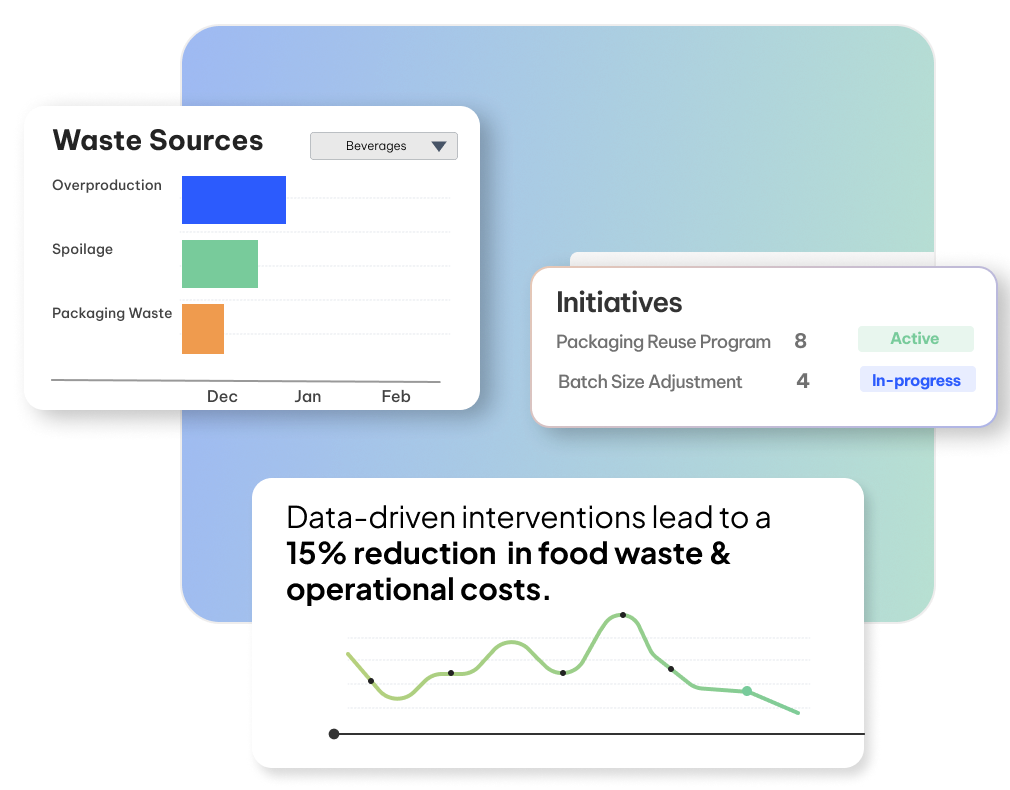

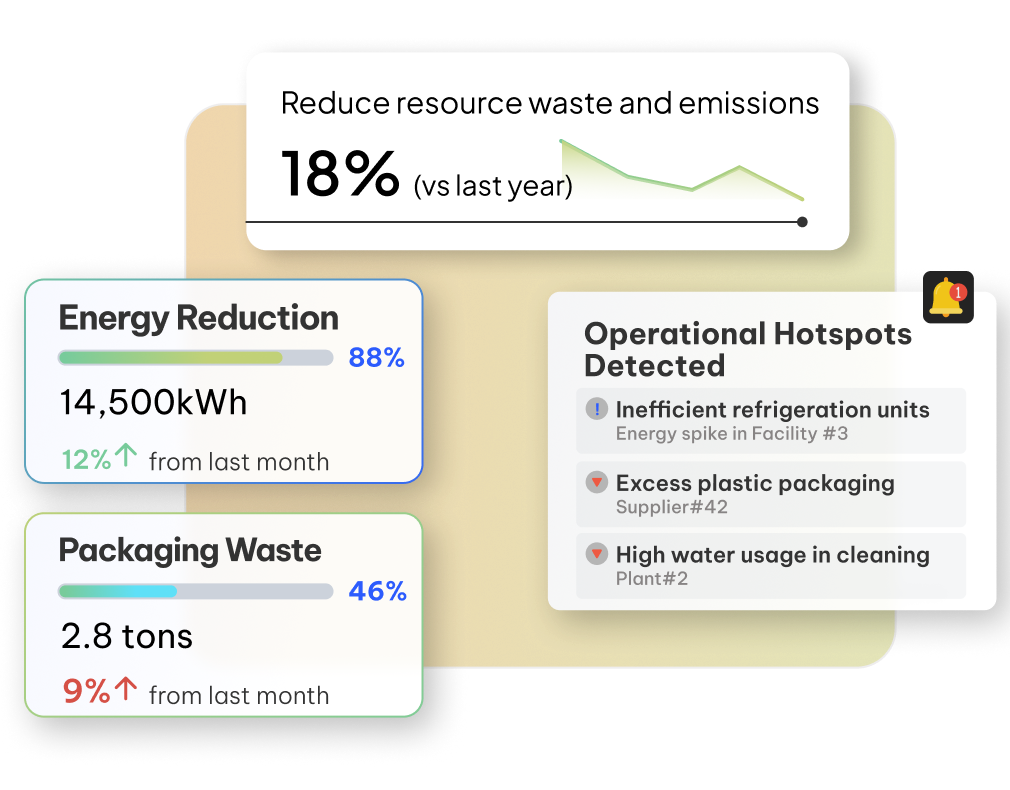

Data-Driven Waste Reduction

POSITIIVPLUS helps you collect and organize operational data to identify areas where waste and inefficiencies occur. Use these insights to implement improvements that reduce spoilage, overproduction, and excess resource usage.

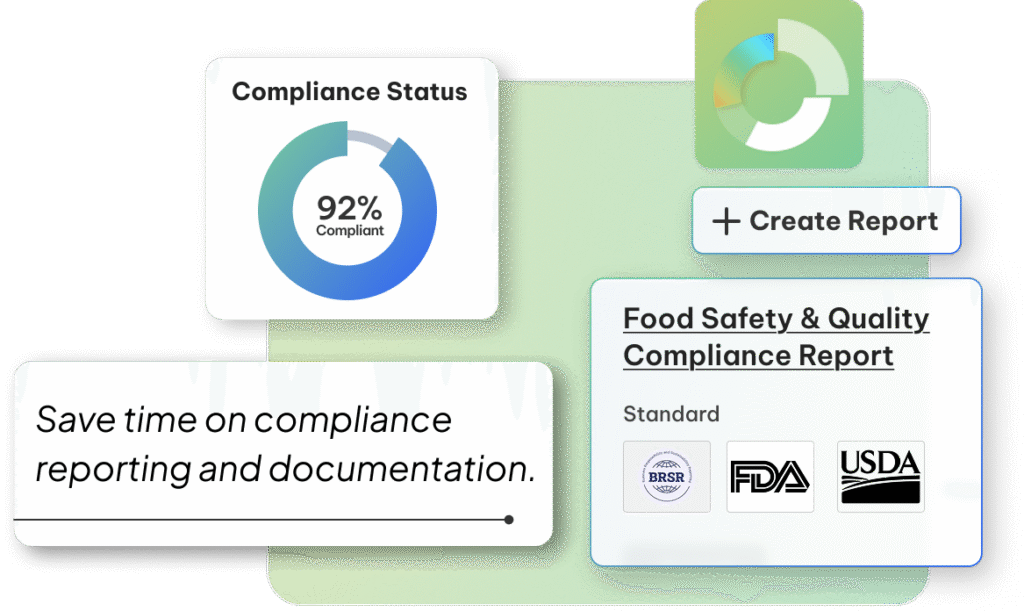

Food Safety Reporting, Streamlined

Generate audit reports, compliance documentation, and supplier scorecards tailored to food safety regulations. POSITIIVPLUS’s flexible Report Builder ensures you can easily meet FDA, USDA, or global standards — with transparency for internal teams, suppliers, and auditors alike.

KPI Tracking for Food Safety

POSITIIVPLUS lets you define targets like batch quality scores, supplier delivery accuracy, and hygiene audit completions. Monitor these KPIs live, benchmark against industry standards, and adjust quickly before small problems impact product safety or brand reputation.

Increase KPI achievement rates to ensure

safer, higher-quality products.

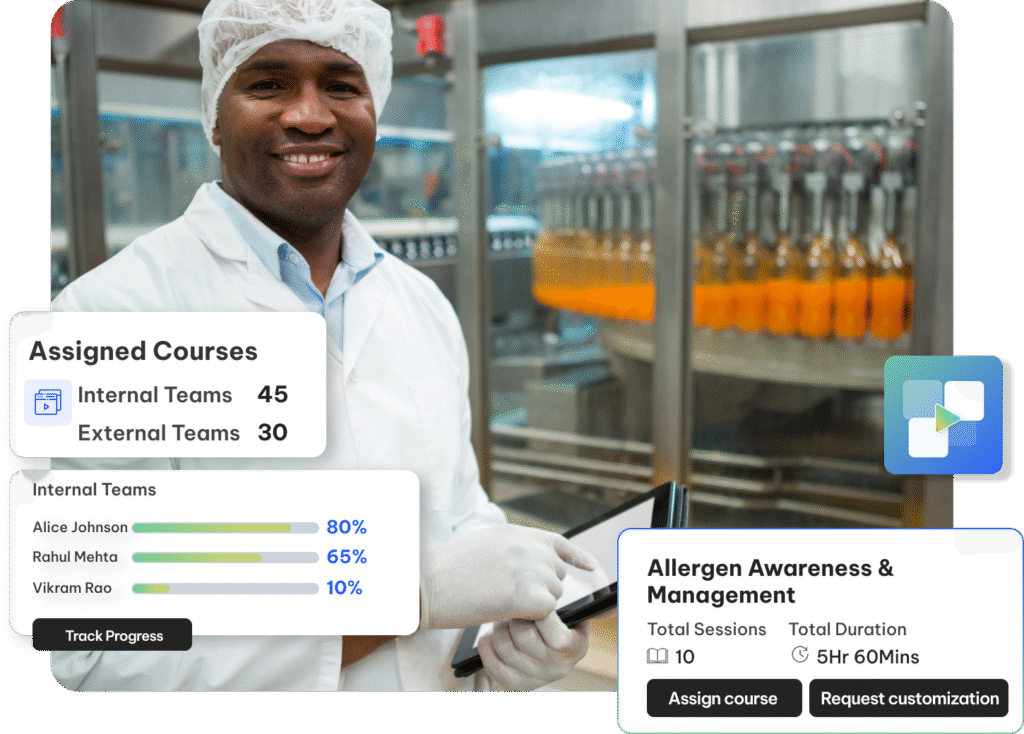

Training for Food & ESG Excellence

Use POSITIIVPLUS’s Training Center to deliver industry-specific courses focused on sustainability best practices, waste reduction, ethical sourcing, and supplier ESG compliance. Equip your staff and vendors with the knowledge to meet evolving ESG requirements and consumer expectations.

Drive training completion across teams,

reinforcing compliance and sustainability culture.

Real Impact on Sustainability

Go beyond compliance by tracking energy use, water consumption, and packaging waste across production and suppliers. POSITIIVPLUS helps you identify hotspots like inefficient refrigeration or excess single-use plastics, assign corrective actions, and transparently report progress to stakeholders.

One Platform to Safeguard

Food Quality, Compliance,

and Sustainability

From ingredient sourcing to delivery, POSITIIVPLUS connects

your entire food operation in one data-driven platform.

FAQ’s

Frequently Asked Questions

How does POSITIIVPLUS help manage supply chain complexity in the food industry?

POSITIIVPLUS provides centralized visibility into your entire supply chain—from raw material sourcing to supplier certifications and delivery schedules. This helps you monitor supplier performance, manage risks proactively, and ensure quality consistency across all touchpoints.

What makes POSITIIVPLUS’s Data Manager unique for food and beverage operations?

Our Data Manager securely collects, structures, and organizes all your operational data—audits, assessments, supplier information, and corrective actions—into one platform. This ensures you can easily analyze trends, identify risks, and make data-driven decisions without juggling multiple systems.

How does the Report Builder support food safety and compliance reporting?

The Report Builder lets you create custom reports tailored to FDA, USDA, HACCP, FSMA, and other regulatory requirements. Generate detailed audit reports, compliance documentation, and supplier scorecards on demand, saving time and ensuring accuracy for internal teams and external auditors.

What role does the Carbon Analyser play in sustainability for food & beverage companies?

The Carbon Analyser tracks Scope 1, 2, and 3 emissions in real time across your production facilities and supply chain. It helps identify high-impact areas like energy-intensive processing or transportation, enabling targeted interventions to reduce your carbon footprint and meet sustainability goals.

Can POSITIIVPLUS handle training for food industry staff and suppliers?

Yes. Our built-in Training Center delivers industry-specific courses focused on sustainability best practices, waste reduction, ethical sourcing, and supplier ESG compliance. This helps you ensure consistent knowledge, regulatory adherence, and stronger supplier partnerships.

How does POSITIIVPLUS ensure data accuracy across multiple production sites?

Our platform consolidates data from all your sites in real time using standardized assessments, audits, and corrective action workflows. This uniform approach guarantees consistent data capture and high-quality information you can trust for strategic decisions.

SaaS in Focus

Insights That Redefine PFood & Bevrages Industry

Practical tools and expert guidance to reduce risks while advancing ESG goals.

Training Food & Beverage Teams and Suppliers

The Hidden Costs of Reactive Waste Management—and

How Real-Time Ingredient Tracking Transforms Quality Control

SaaS for Businesses. SaaS for the Planet.

Parent Company:

Company

Platform

Pricing

Impact

Privacy

Terms

Features

Foundation

Assessments

Actions

Training Center

Data Manager

Carbon Analyzer

Report Builder

Contact Details

- SCF-136, Faridabad

- info@positiivplus.com

- +91-7780018001