Programs That Build Greener Operations in Packaging

Packaging

Drive Efficiency, Safety, and Sustainability — Into Every Package

From sourcing materials to sealing, labelling, and compliance, POSITIIVPLUS connects every step of packaging production. Manufacturers cut waste, improve margins, and meet ESG targets with one integrated platform.

The SaaS Edge

Connected Packaging Workflows

All activities — sourcing, converting, printing, and dispatch — are brought together in POSITIIVPLUS Data Manager. Assessments, audits, and actions stay organized in one place, ensuring nothing slips through the cracks.

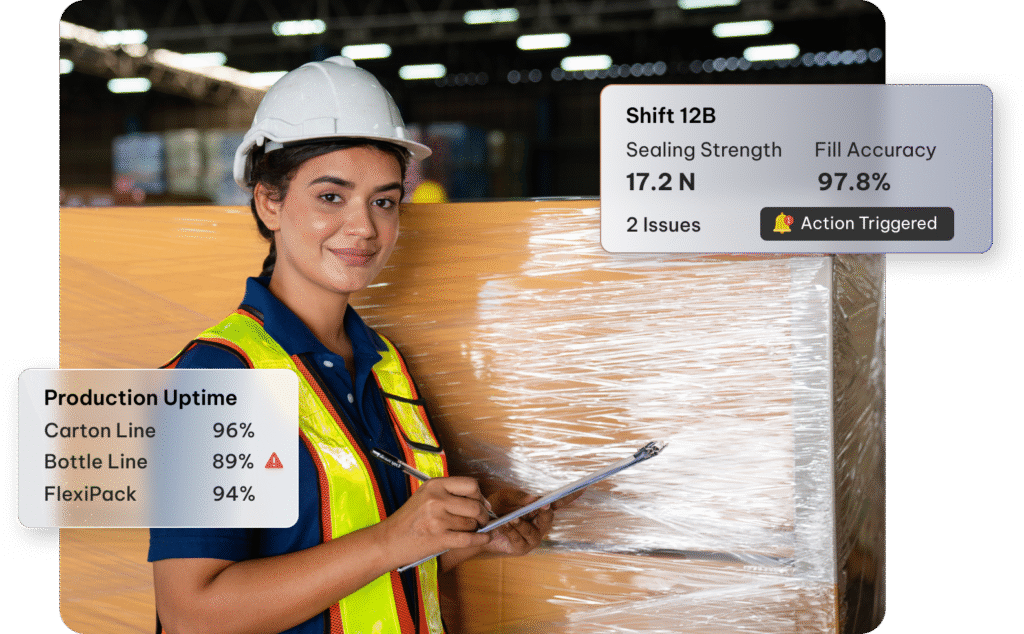

Production Decisions in Real Time

Dashboards detect machine stoppages, sealing flaws, or line slowdowns the moment they occur. Managers get clear visibility and can trigger corrective actions instantly.

Sustainability That Pays Off

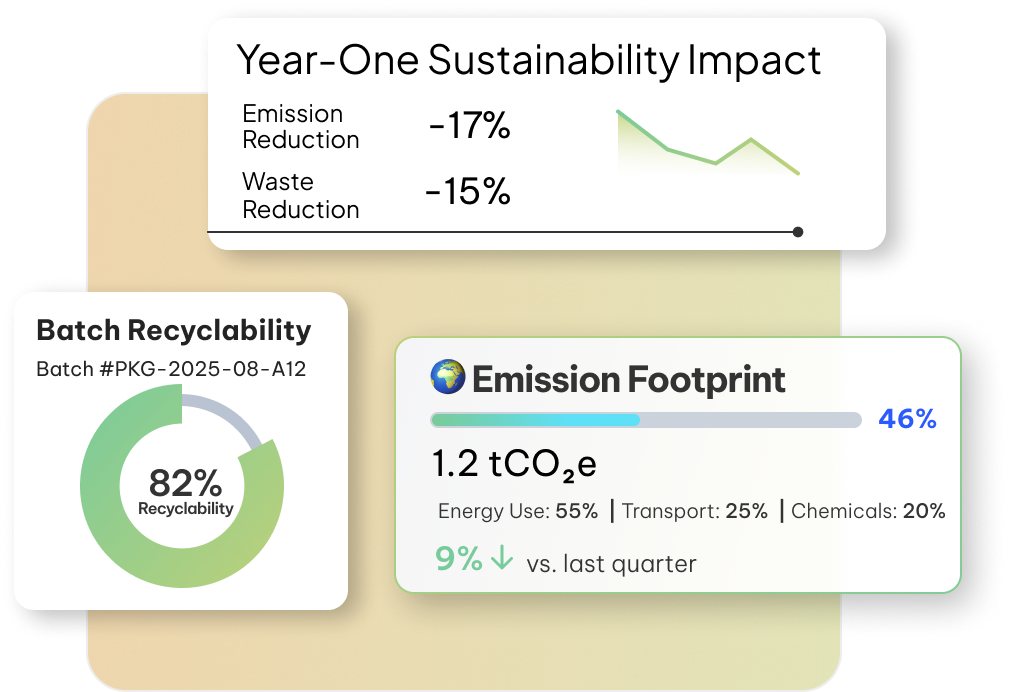

With Carbon Analyser & Report Builder, plants uncover hidden inefficiencies, document improvements, and meet recycling or emissions standards — turning environmental performance

into measurable cost savings.

What’s Possible

How POSITIIVPLUS Elevates

Packaging Manufacturing

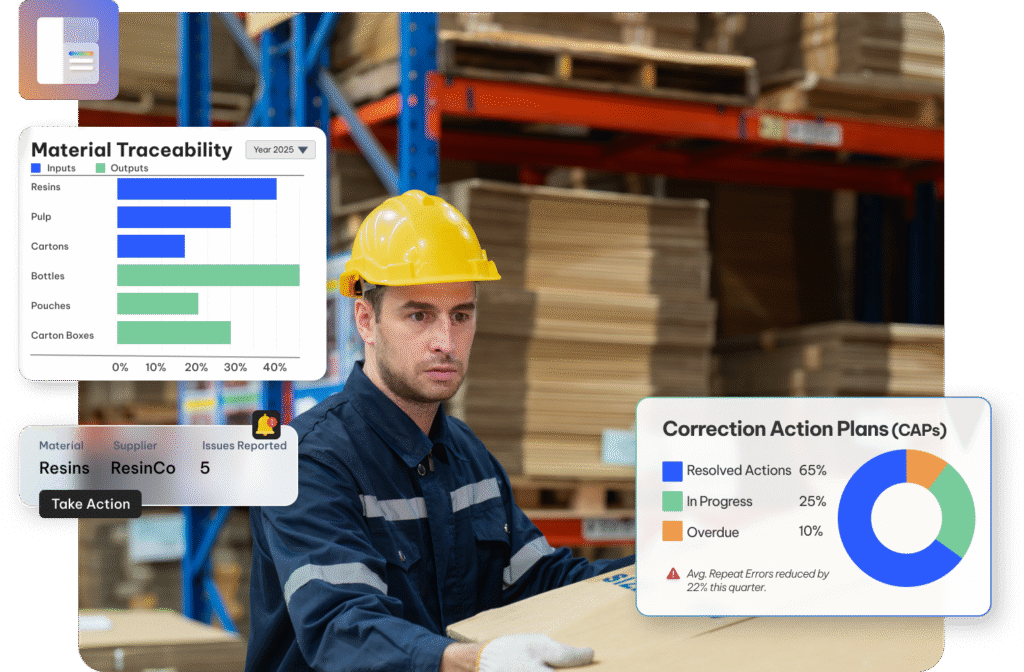

Total Batch Traceability

Across Supply Chains

From resins and pulp to cartons, bottles, and flexible packs, Data Manager records every input and output. When issues arise, teams trace them back to a supplier or process in minutes and assign actions to prevent repeat errors.

Prevent unexpected disruptions, keep production flowing.

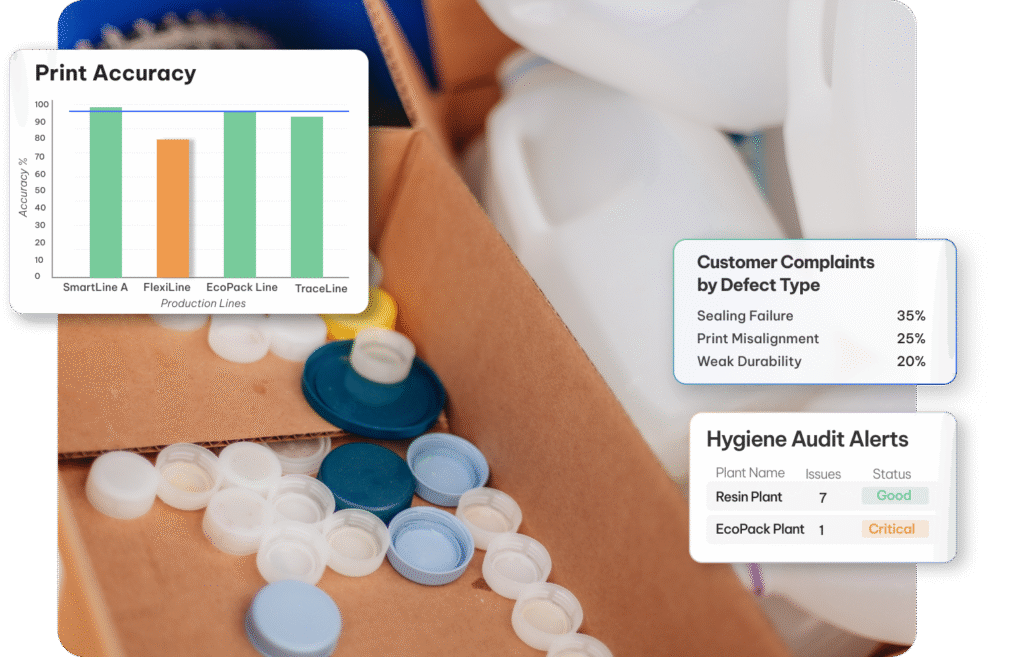

Quality Embedded at Every Stage of Production

Durability tests, sealing checks, print accuracy, and hygiene audits are digitized and standardized across facilities. Corrective measures are tracked automatically, ensuring smooth audits and fewer customer complaints.

Ensure quality checks at every stage, always.

Simplified Global Compliance and Standards

Report Builder streamlines packaging standards including FDA, EU Waste Directive, FSC®, BRCGS Packaging, and ISO certifications. With assessments tied directly to compliance templates, reports are audit-ready and exportable at a click.

Resource Efficiency Unlocked for Plants

Carbon Analyser highlights overuse of scrap, water, or energy at line level. Linked corrective actions ensure plants target their biggest inefficiencies first, creating quick wins in both sustainability and cost reduction.

Actionable KPIs for Smarter Supervisors

POSITIIVPLUS tracks uptime, sealing strength, fill accuracy, and defect ratios across shifts. With live indicators connected to automated tasks, risks are fixed before they grow into larger disruptions.

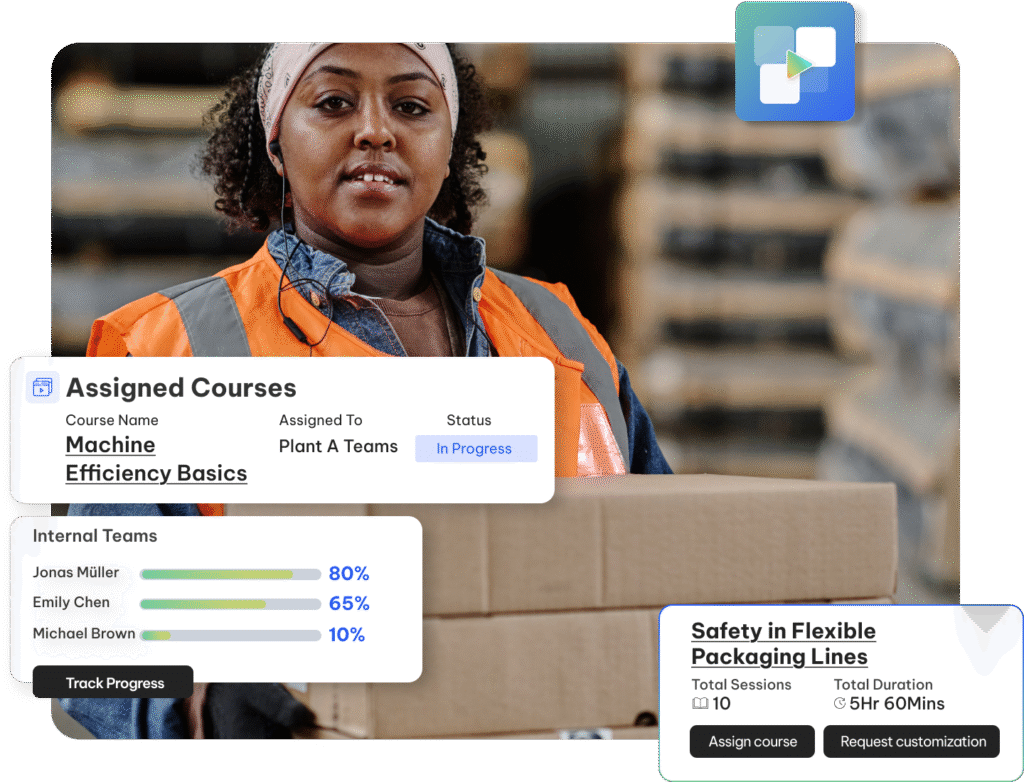

Skilled Teams, Ready for Tomorrow

Training Center offers packaging-specific modules on safety, hygiene, machine efficiency, and ESG practices. Certifications and completions are logged centrally, keeping plants compliant and teams’ future-ready.

Proof of Sustainability for Every Buyer

By linking recyclability scores, emission reductions, and waste metrics to production batches, POSITIIVPLUS enables brands to give retailers and regulators transparent, verifiable sustainability data.

One Platform. Every Plant.

End-to-End Visibility.

From raw material inputs to packaged products — efficiency,

compliance, and sustainability in one system.

FAQ’s

Frequently Asked Questions

How does POSITIIVPLUS adapt to different packaging operations — plastics, paper, glass, or metal?

The platform captures universal needs such as traceability, audits, and corrective actions, while tailoring workflows to material-specific processes. For example, plastics can track sealing and leakage rates, paper facilities log FSC® compliance, and glass plants monitor furnace efficiency. All data stays unified, so leadership gets a consolidated view.

Which quality and compliance standards are supported?

POSITIIVPLUS Report Builder includes templates for FDA packaging rules, EU Packaging Waste Directive, FSC®, BRCGS Packaging, ISO 9001/14001, and regional legislation. Plants digitize inspections, attach supporting records, and generate proof of compliance instantly — reducing both audit prep time and regulatory risks.

How does the platform help reduce environmental impact?

The Carbon Analyser measures scrap, emissions, and utilities across all production lines. These insights are directly linked to Data Manager actions, so teams can act on findings instead of just reporting them. Progress aligns with frameworks like the GHG Protocol, FSC®, and Extended Producer Responsibility (EPR), ensuring external reporting is backed by evidence.

What kind of staff training can I roll out?

The Training Center offers modules on packaging hygiene, machine operations, quality systems, waste reduction, and ESG. Managers can assign courses by role — operators, supervisors, or quality leads — while completions and certifications are logged automatically. This ensures skills stay current, compliance is met, and workforce gaps are filled before they affect production.

Does POSITIIVPLUS integrate with existing systems?

Yes. ERP, MES, SCM, and inventory systems connect seamlessly via APIs. POSITIIVPLUS enriches this data with compliance, audit, and ESG insights, eliminating silos. Instead of replacing existing tools, it enhances them, giving managers and executives a holistic picture of plant performance.

SaaS in Focus

Insights That Redefine Packaging Manufacturing

Practical strategies for efficiency, compliance, and sustainability in packaging.

Sustainable Packaging Production Without Complexity The packaging

Costs of Scrap and Idle Time in

Time Data to Eliminate Packaging Line Defects

SaaS for Businesses. SaaS for the Planet.

Parent Company:

Company

Platform

Pricing

Impact

Privacy

Features

Foundation

Assessments

Actions

Training Center

Data Manager

Carbon Analyzer

Report Builder

Contact Details

- info@positiivplus.com

- +91-7780018001