Building a Skilled Workforce for Greener Mills

Textiles

Weave Efficiency, Quality, and Sustainability — Into Every Fabric

From sourcing to production and compliance, POSITIIVPLUS helps textile manufacturers achieve operational clarity, cost efficiency, and ESG compliance — across every facility, every time.

The SaaS Edge

Unified Textile Operations

Bring together raw material sourcing, production stages, chemical handling, and vendor management in one platform — no scattered records, no manual headaches.

Production Decisions, Powered by Data

Live dashboards surface machine downtime, defect spikes, and supply bottlenecks — so managers can act fast before they affect delivery schedules.

Lean, Green, and Profitable

Cut energy and water use, optimize production flow, and reduce waste — proving measurable gains in efficiency, margins, and sustainability credentials.

What’s Possible

How POSITIIVPLUS Strengthens

Textile Manufacturing

Every Process, One Dashboard

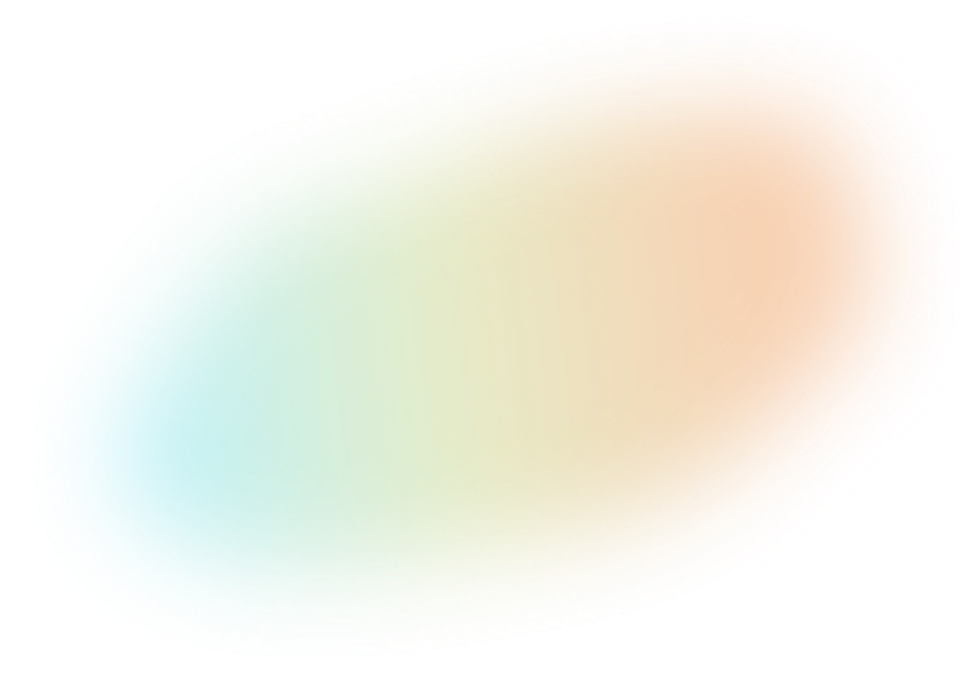

With POSITIIVPLUS Data Manager, every step — from cotton fields to finished fabric — is captured in one place. Managers can trace each roll of fabric back to its origin, quickly isolate issues, and keep production moving without delays.

Get instant insights on operational performance & production flow.

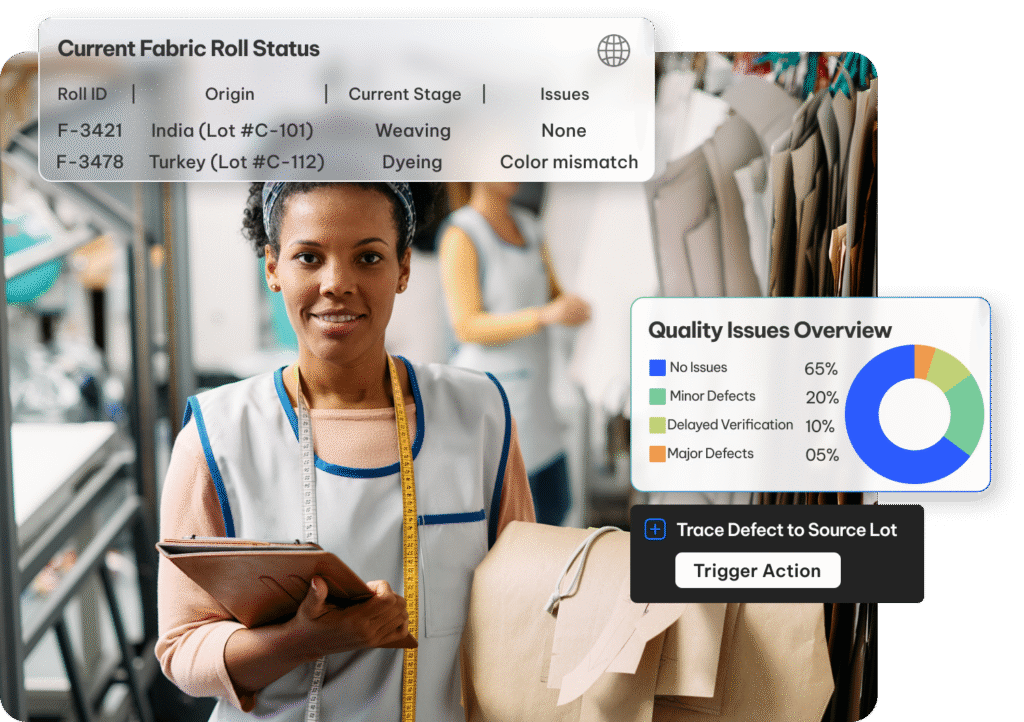

Consistent Quality, Every Time

Quality checks, audits, and corrective actions are no longer scattered across spreadsheets. Stored and managed in the Data Manager, these processes stay consistent across dyehouses, stitching units, and supplier sites, ensuring smoother operations and faster fixes.

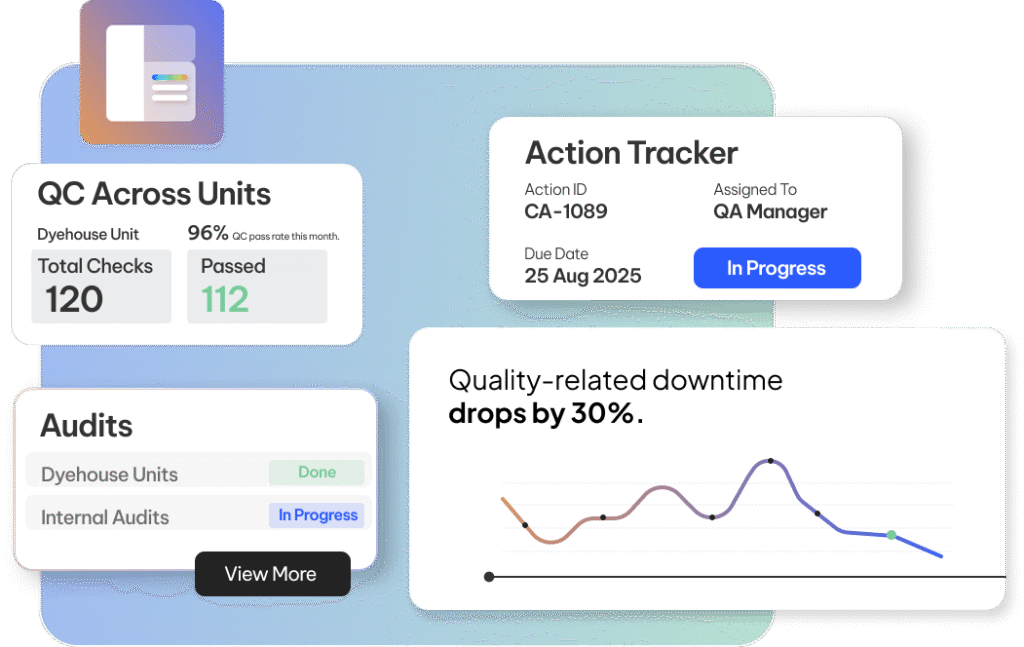

Compliance Without Complexity

The Report Builder makes it simple to meet global standards like REACH, OEKO-TEX®, GOTS, ZDHC, ISO 14001, and labor requirements. Pre-built templates standardize checks, while exportable reports give buyers and regulators the proof they need instantly.

Reduce compliance violations and improve operations.

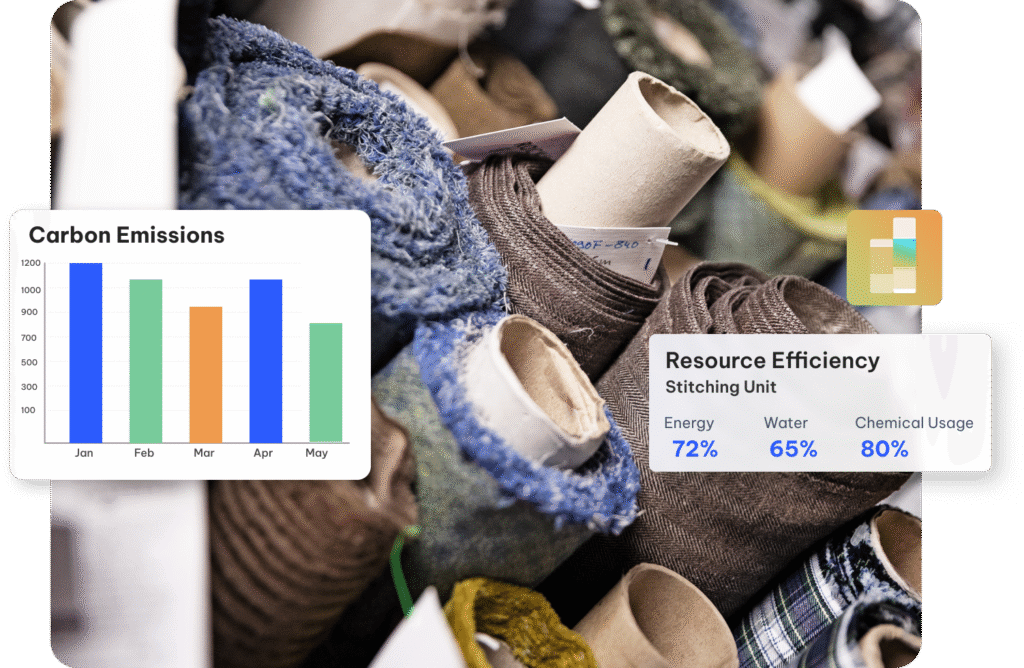

Turning Waste Into Efficiency

POSITIIVPLUS Carbon Analyser pinpoints where energy, water, chemicals, and emissions are being wasted across facilities. These insights make it possible to cut costs, optimize resources, and improve sustainability performance year over year.

“

Drive meaningful resource savings from year one.

”

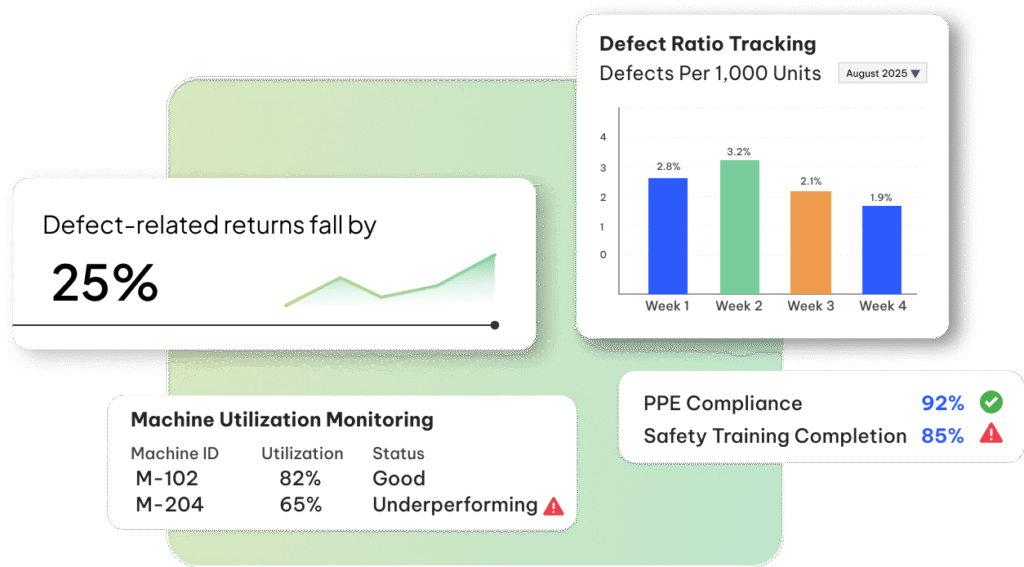

Live KPIs That Safeguard Quality

By tracking machine utilization, defect ratios, turnaround times, and worker safety compliance in real time, POSITIIVPLUS helps supervisors see risks before they escalate. With clear KPIs, root-cause fixes are faster and more precise.

Workforce Ready for Tomorrow

Through the Training Center, teams can access targeted courses on machinery, safety, chemical handling, and sustainability. Every completion is tracked, ensuring workforce skills always align with production needs and ESG goals.

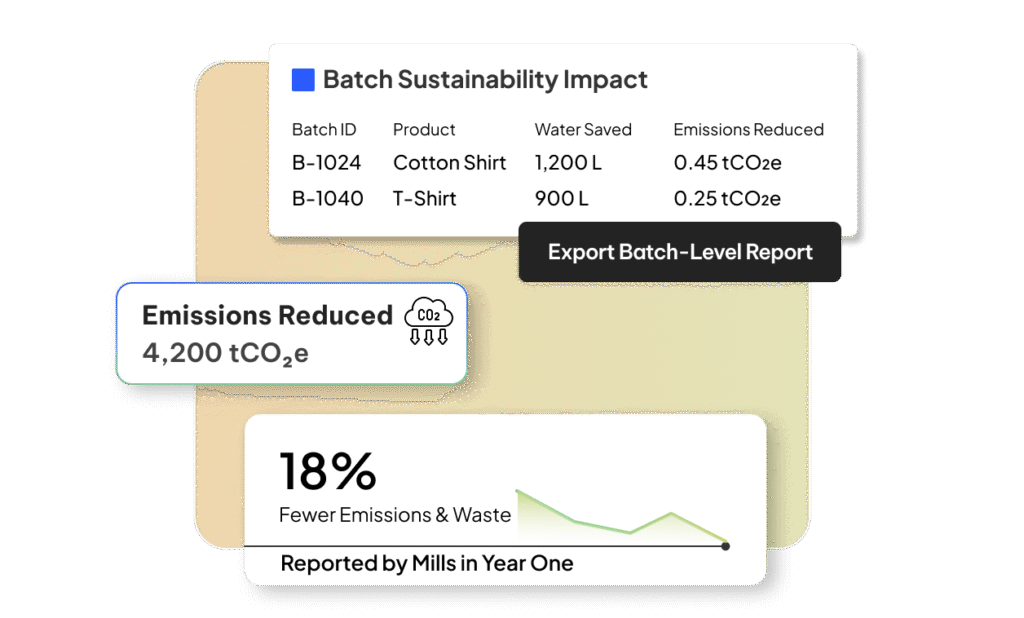

Sustainability Woven In

Carbon Analyser and Report Builder link sustainability results — like water savings, lower emissions, or reduced waste — directly to product batches. This gives brands the ability to share transparent and credible progress with buyers and certification bodies.

One Platform. Every Mill.

Complete Visibility.

From fiber to finished product — achieve efficiency,

compliance, and sustainability at scale.

FAQ’s

Frequently Asked Questions

How does POSITIIVPLUS adapt to different textile operations — spinning, weaving, dyeing, or finishing?

It standardizes core processes like tracking fiber, loom efficiency, dye bath accuracy, and finishing checks, while allowing plant-specific workflows and regional compliance requirements.

Which quality and compliance standards does POSITIIVPLUS support?

Pre-loaded templates with REACH, OEKO-TEX®, GOTS, ZDHC, ISO 9001/14001, and local laws. Factories can digitize audits, automate reminders, and generate export-ready compliance reports.

How does the platform help reduce environmental impact?

The Carbon Analyser tracks emissions, water, chemicals, and energy across sites. Reports align with GHG Protocol, OEKO-TEX® STeP, GOTS, and ZDHC to prove measurable progress.

What kind of staff training can I roll out?

Interactive modules cover machine safety, chemical handling, quality, ESG, and sustainability. Skills are mapped to production needs so managers plug gaps before they affect output.

Does POSITIIVPLUS integrate with ERP, SCM, and production systems?

Yes — via APIs and connectors. Data from ERP, MES, SCM, and inventory flows into one view, enhancing existing systems with compliance and ESG insights.

SaaS in Focus

Insights That Redefine Textile Manufacturing

Stay ahead with strategies on efficiency, compliance, and sustainability in textiles.

Sustainable Textile Production Made Simple The fashion

The Hidden Costs of Downtime in Textile

Why Real-Time Data Enhances Quality Control in

SaaS for Businesses. SaaS for the Planet.

Parent Company:

Company

Platform

Pricing

Impact

Privacy

Features

Foundation

Assessments

Actions

Training Center

Data Manager

Carbon Analyzer

Report Builder

Contact Details

- info@positiivplus.com

- +91-7780018001