Workforce Training for the Future of Mobility

Automotives

Build Smarter, Safer, and Greener Vehicles

From sourcing components to assembly, testing, and compliance, POSITIIVPLUS gives automakers full visibility across operations. Improve part quality, reduce recalls, and cut emissions — all within one connected platform.

The SaaS Edge

Connected Operations Across Boundaries

Assessments, audits, and actions are unified across sites, suppliers, and product lines. With one platform, gaps close faster and every improvement is tied back to measurable outcomes.

Clarity for Better Decisions

Live dashboards surface risks — whether downtime, defects, or non-compliance — in real time. Leaders gain visibility that supports quick, confident action across global operations.

Sustainability You Can Prove

Energy, water, emissions, and waste are tracked continuously. Compliance and ESG reports are auto-generated to align with international standards, making progress transparent and verifiable.

What’s Possible

How POSITIIVPLUS Drives

Automotive Manufacturing

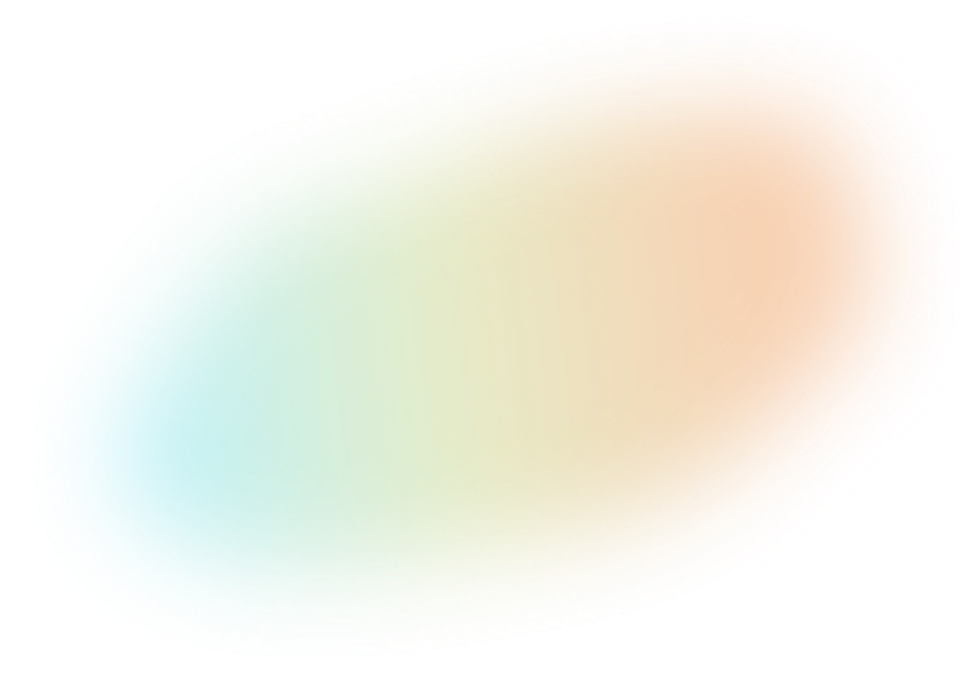

End-to-End Supplier

Traceability for Parts

From steel and plastics to batteries and semiconductors, Data Manager logs every supplier input and quality record. When issues surface, automakers can pinpoint the exact vendor or batch in minutes and trigger corrective actions and generate assessments instantly.

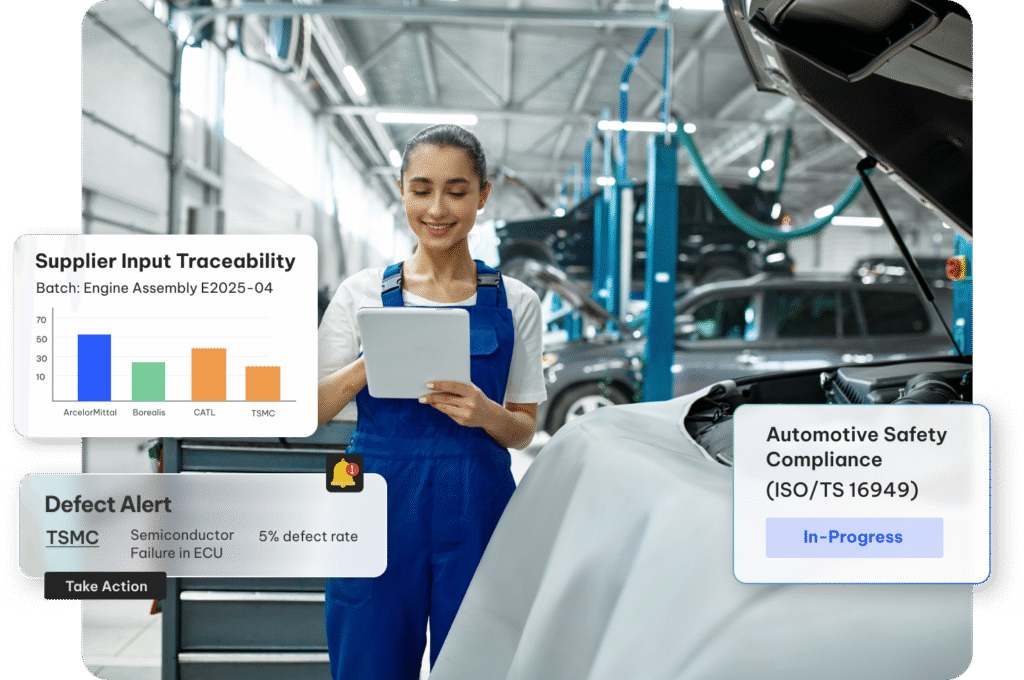

Assembly Line Quality

Embedded Everywhere

Weld inspections, torque checks, paint quality, and crash test records are digitized and standardized across plants. Corrective measures are connected directly to audits, ensuring zero tolerance for recurring failures.

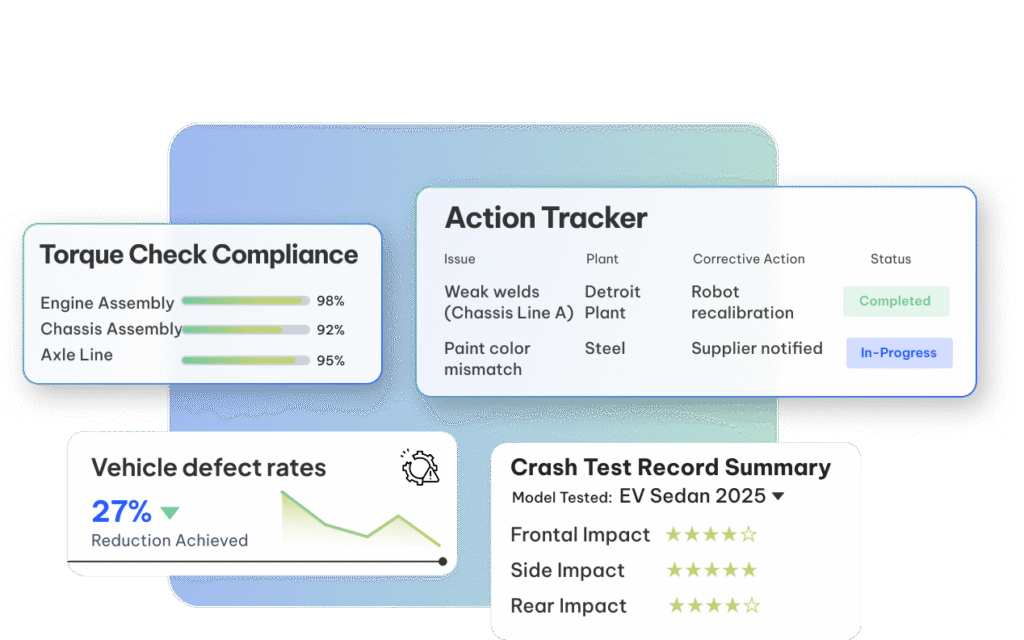

Global Automotive Standards Simplified

Report Builder supports ISO/TS 16949, IATF 16949, ISO 9001, EU vehicle safety directives, and regional regulations. Reports are pre-structured, audit-ready, and exportable at a click — cutting compliance workload in half.

“

Automate reporting to save time and focus on high-value work.

”

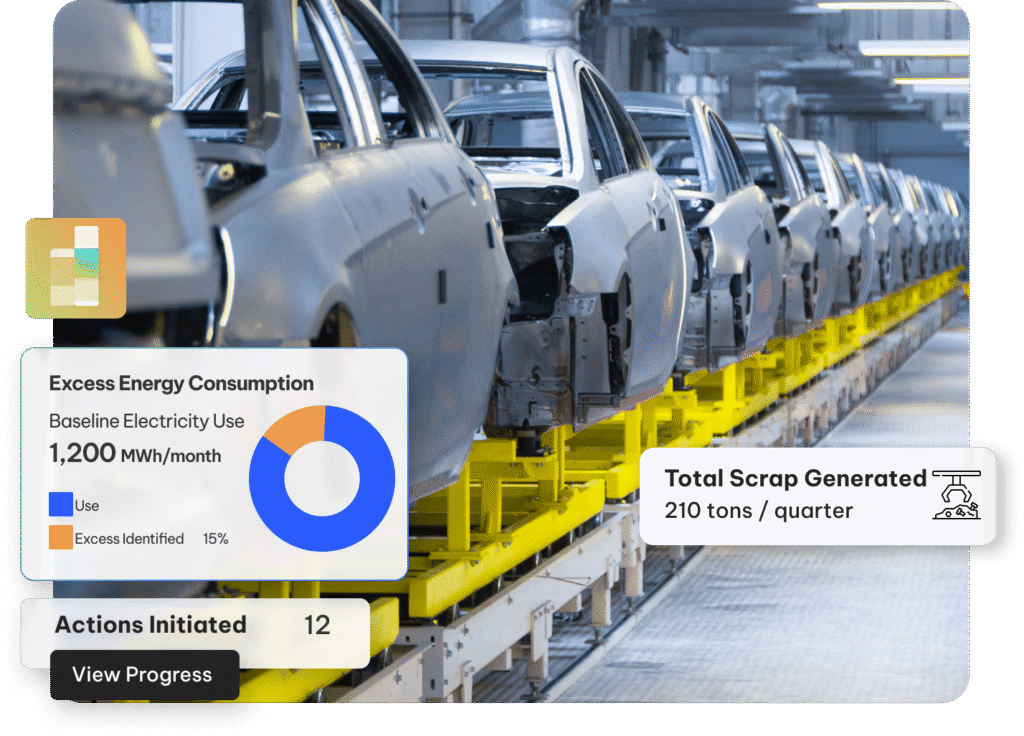

Resource Efficiency Across Complex Plants

Carbon Analyser identifies excess fuel, electricity, water, or scrap at the production line and facility level. Linked corrective actions help target the highest-cost inefficiencies first, creating rapid payback on ESG goals.

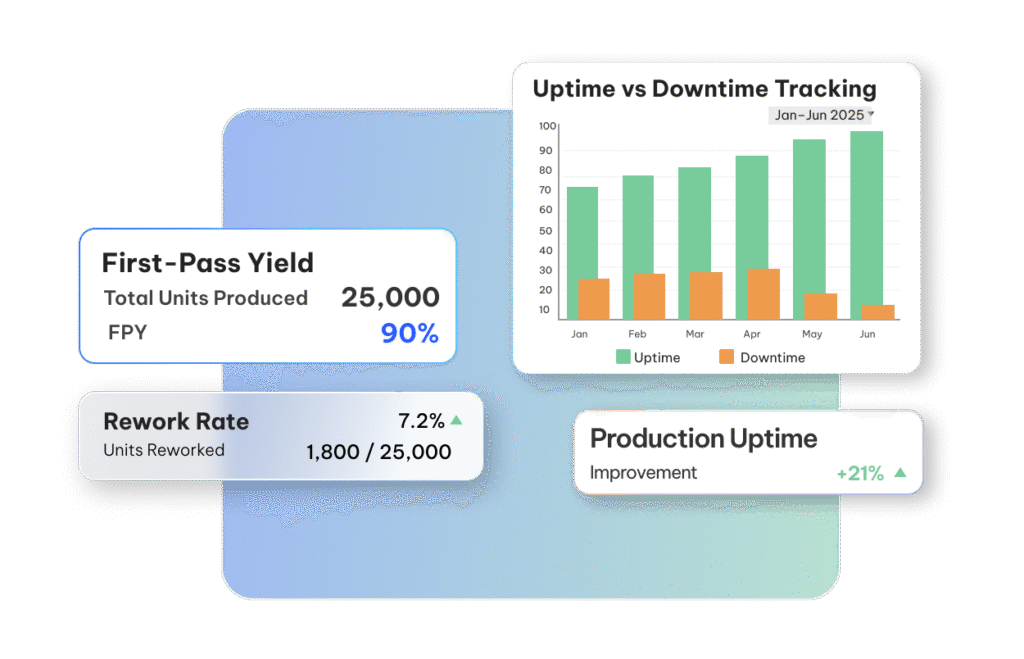

Actionable KPIs for Plant Managers

Track cycle times, first-pass yield, downtime, and rework rates across all assembly lines. With automated alerts and action tracking, POSITIIVPLUS helps teams resolve risks before they trigger stoppages.

Track key metrics to keep production efficient & on target.

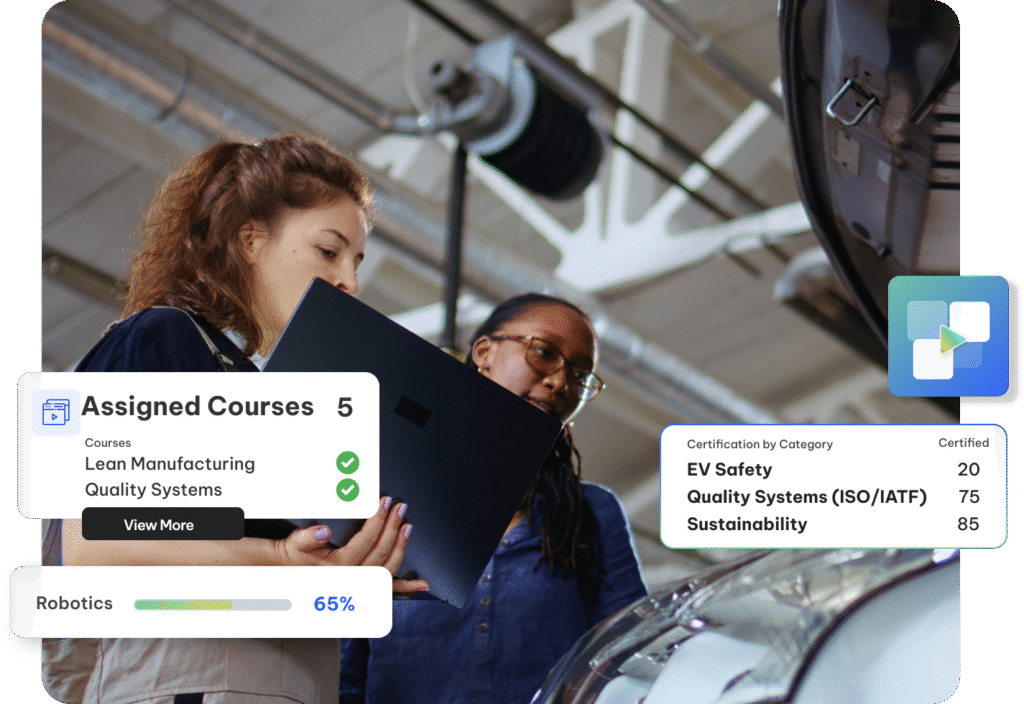

Workforce Training for Next-Gen Mobility

Training Center equips staff with courses in lean manufacturing, EV safety, robotics, quality systems, and sustainability. Certifications are tracked centrally, ensuring readiness for evolving industry demands.

Equip staff with hands-on training for consistent assembly quality.

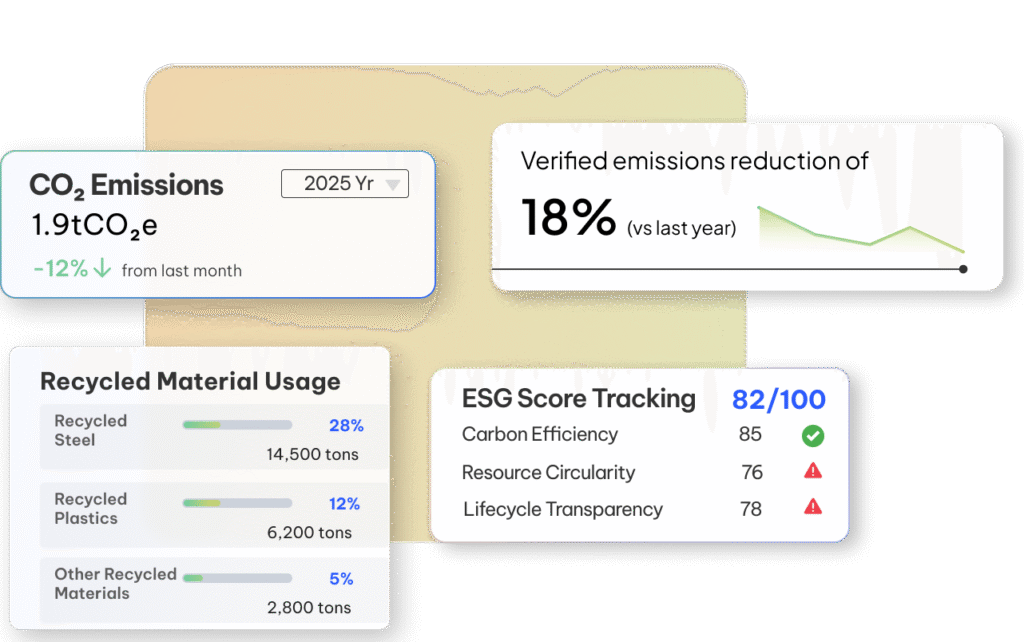

Verified Sustainability for Regulators and Buyers

POSITIIVPLUS links emission reductions, recycled content, and lifecycle metrics to production records. Automakers gain transparent proof for ESG reporting and consumer trust.

From Supply Chain to

Showroom — One Platform

for Automotive Excellence

Trace every component, streamline every process, and build vehicles

that meet the highest standards of safety and sustainability.

FAQ’s

Frequently Asked Questions

How does POSITIIVPLUS adapt to automotive supply chain complexity?

The platform integrates tier-1, tier-2, and raw material suppliers into one connected system. Quality checks, compliance audits, and corrective actions are logged centrally, giving automakers full control and traceability — even in global, multi-tier supply chains.

Which automotive standards and regulations are supported?

Report Builder includes templates for IATF 16949, ISO/TS 16949, ISO 14001, ISO 9001, EU vehicle safety directives, and regional emissions regulations. Reports combine audit findings with supporting records, making compliance evidence easy to share with regulators or OEM partners.

How does POSITIIVPLUS support ESG and carbon reduction in plants?

Carbon Analyser tracks energy consumption, waste, water usage, and CO₂ emissions across plants. These insights are tied directly to Data Manager corrective actions, ensuring teams move from reporting to measurable reductions aligned with GHG Protocol and global automotive ESG standards.

What kind of staff training can automakers roll out?

Training Center provides modules for EV battery handling, robotics, lean manufacturing, vehicle safety testing, ESG awareness, and compliance. Supervisors can assign by role, track completions, and close training gaps that impact production quality or compliance.

Does POSITIIVPLUS integrate with automotive ERP and MES systems?

Yes. POSITIIVPLUS connects with ERP, MES, PLM, and SCM systems via APIs. It adds ESG, compliance, and audit insights to existing data, eliminating silos and enabling decision-making across engineering, quality, and sustainability teams.

SaaS in Focus

Insights That Redefine Automotive Manufacturing

Explore strategies to boost quality, reduce recalls, and build sustainable operations.

EV Manufacturing and Carbon Reduction Roadmaps The

IATF 16949 Compliance Made Simple in Automotive

Reducing Automotive Recalls with Data Manager Automotive

SaaS for Businesses. SaaS for the Planet.

Parent Company:

Company

Platform

Pricing

Impact

Privacy

Features

Foundation

Assessments

Actions

Training Center

Data Manager

Carbon Analyzer

Report Builder

Contact Details

- SCF-136, Faridabad

- info@positiivplus.com

- +91-7780018001